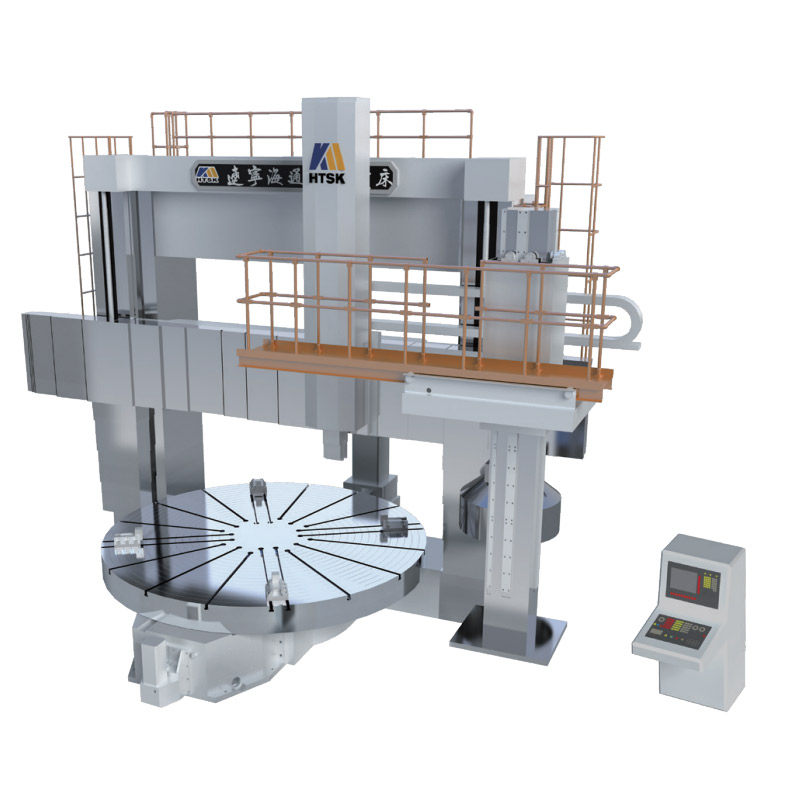

This series of machine tools is a fully closed-loop three-axis (X, Z, C) CNC vertical turning and milling machining center with turning as the main tool and milling as the auxiliary tool. One machine with multiple functions, controlled by CNC, organically combines functions such as turning, boring, drilling, grinding, and worktable indexing and feed. It can clamp workpieces at once and complete multiple machining processes. It can improve the accuracy of workpiece position and machining efficiency.

Turning function: capable of turning inner and outer cylindrical surfaces, end surfaces, conical surfaces, threading, and constant line speed turning.

Milling function: capable of milling end face cam, radial cam, etc.

Drilling and boring function: The workbench has arbitrary indexing and positioning functions, and can drill and bore horizontal or vertical holes.

Grinding function: The tool holder is equipped with a 400 diameter grinding wheel head, which can grind inner holes or outer circles.

Application scope: Mainly used in mechanical manufacturing industries such as power generation equipment, light industry machinery, large bearings, and general machinery.